Materials

From Living Building Science

Contents

- 1 Introduction to System of Study

- 2 Specifics of System used in Kendeda

- 3 Catalyst Application in Wood Acetylation

- 4 Milestones

- 5 Analogous Systems

- 5.1 Hitchcock Center for the Environment (Amherst, MA)

- 5.2 Sustainable Buildings Research Centre (Wollongong, Australia)

- 5.3 Frick Environmental Center (Pittsburgh, PA)

- 5.4 Old Oak Dojo (Boston, MA)

- 5.5 Macquarie University Innovation Hub (Australia)

- 5.6 Tashjian Bee Pollination Center @ University of Minnesota (Minneapolis, MN)

- 5.7 Copenhagen University - "The Wild Campus" (Denmark)

- 6 Annotated Bibliography

- 7 Team Members

Introduction to System of Study

The Kendeda Building for Innovative Sustainable Design is championed as the most sustainable building in the southeastern United States. The building meets the criteria for the Living Building Challenge 3.1, a huge accomplishment for a building of its size in an urban environment. The Living Building Challenge consists of seven performance categories, or “Petals”, which were created to mirror the buildings comparison to a being, such as a flower, and include: Place, Water, Energy, Health & Happiness, Materials, Equity and Beauty. Our team has decided to focus on the "Materials" petal of the Living Building Challenge. There are specific requirements that the building must follow with regards to sustainable building materials. Some of these requirements include the use of salvaged materials and the exclusion of Red List chemicals. One of the principle components of the building is Accoya® wood, which is known for its durability and anti-pest properties, and is one of the first of its kind to achieve such a high increase in durability without the use of harsh chemicals. Accoya® manufactures acetylated wood and is a common building material in Europe and Asia but its popularity has not yet spread to the United States. This results in high transportation costs as the wood is shipped from Europe and Asia to several distribution centers before it reaches its final destination.

Due to the fact that Accoya® wood is generally unsustainable due to these fossil fuel costs, our team is interested in investigating the interactions and potential effects of varying catalysts on acetic anhydride in the acetylation reaction. We hope to make the process of acetylating wood more sustainable and efficient so that the wood can be manufactured closer to home, in order to pave the way for future Living Buildings.

Specifics of System used in Kendeda

Salvaged Materials

The Kendeda Building has made extensive use of salvaged materials throughout the space. Under Living Building Challenge 3.1, each project must incorporate one salvaged material per 500 square meters of gross building area. This results in 10 different salvaged materials throughout the building. Some of these materials in place currently include:

- Recycled slate shingles from Georgia Tech Alumni Association building that can be seen on the interior of the restrooms

- Two-by-fours from a demolished film sets were

- Granite curbs from Georgia State Archives Building (Stone Mountain) are used on the curb surrounding the constructed wetland

- Heart pine joists initially from Tech Tower

- Lumber from storm-felled trees on Georgia Tech's campus

- Wood trimmed from local nail laminated timber used for internal stairs

Accoya Wood

Another notable building material that was used in the construction of the Kendeda Building is Accoya wood, that can be seen on the exterior of the second floor of the building. It is Radiata Pine wood that has been acetylated by acetic anhydride. The acetylation process results in the substitution of hydroxyl groups by acetyl group in a glucose unit of the cellulose, which is the building stone of the wood fibers. The substitution reduces the hydrophilicity of the wood due to the decrease in hydroxyl group content, and this causes the reduction in water absorption of the treated wood.

Catalyst Application in Wood Acetylation

Project Objective: The objective of this experiment is to explore how different catalysts used in wood acetylation improve the performance of the resulting product. The team intends to find out the most sustainable way of treating wood that would result in the desired dimensional stability, anti-swelling properties, hardness, and water absorption properties. The end goal is to determine the catalyst-reaction pair that would result in minimal waste and environmental impact, and it is achieved through assessing the catalyst’s minimal optimal-functioning concentration, effectiveness, and the potential environmental impact resulting from its incorporation.

Research Hypothesis: If the concentration of the catalysts are acetylated with their optimal concentrations, then zinc chloride is the best catalyst due to the great increase in WPG and anti-swelling efficiency (He, 2019). If the concentration of catalysts are standardized to a smaller amount and only modified through heat, then potassium acetate is the best catalyst (Obataya, 2009).

Catalyst Information

Our team studied a variety of academic literature to evaluate the effectiveness of potential catalysts based on a specific set of criteria, which include:

- Projected Weight Percentage Gain (WPG)

- Temperature range

- Predicted Dimensional Stability increase

- Potential environmental impacts

Based on the criteria, our team was able to select 5 catalysts that we feel would be a good fit for our experiment. We have gathered some information about each catalyst and its potential implications in wood acetylation.

Potassium Acetate

- 2 minutes required for 20% weight gain at 120 degrees C

2 step-process to acetylation:

- Soak wood in KAc followed by drying

- Soak wood in acetic acid with elevated temperatures

- New experimental process combining the two procedures at incredibly high temperatures

Zinc Chloride

- Of all catalysts (in prior experiment from academic literature), yielded highest net WPG

- Process similar to most acetylation procedures (mix catalyst w/ anhydride, soak wood in reduced and normal pressure, leached in water and then acetone, oven-dried)

N-Bromosuccinimide (NBS)

- Presence at concentrations between 1.0% and 3.0% greatly elevated acetylation rate

- WPG with 2% NBS catalyst, after 60 min at 120*C: 22.1%

Sodium Acetate

- Concentration on 0.1-1% for best results

- Similar acetylation process to zinc chloride

4-Dimethylamino Pyridine (DMAP)

- Concentrations of 3% and 5%

- Exhibited the fastest rate of reaction

Wood Acetylation Procedure

- The loblolly pine samples will be cut and sanded from a plank of wood, into the dimensions 15*15*15 mm. The pine cubes will be subjected to the standard oven-drying procedure at 105°C overnight to get rid of any excess moisture prior to acetylation.

- An apparatus composing of a three-neck, 500 mL 34/45 round-bottomed flask, a reflux condenser with a cold finger, stoppers, and a beaker to serve as the hot water bath will be used to perform the acetylation reaction. The flask will have a reflux condenser on the middle neck and two stoppers on the other necks during the reaction. The flask will be clamped and placed in the beaker, all of which is placed on top of a hot plate in order to heat the water. The boiling water bath will be used to reduce any swelling of the wood samples during the acetylation and to prevent any thermal degradation.

- Due to time and glassware limitations, the only catalyst we will use for now is N-Bromosuccinimide (NBS). NBS will be used at 3% percent weight to catalyze the reaction. This concentration was found to be the most optimal concentration that yielded the most effective use of the catalyst in this application, as determined from past experiments. 150 mL of acetic anhydride will be mixed with 4.5 grams of NBS and swirled in order to dissolve the solid. The wood cubes and the catalyst solution will be heated to boiling and allowed to soak for three hours. The samples will float in the solution, so the flask will be occasionally swirled in order to maximize the penetration of the solution into the wood on all sides.

- Following the acetylation reaction, the cubes and solution will be allowed to cool. The cubes will be decanted and allowed to dry briefly over a mesh strainer placed in a beaker. The cubes will then be oven-dried again at 105*C overnight. Following the drying procedure, the cubes will be subjected to tests of their hardness, flexibility, and dimensional stability in order to determine how the catalysts and acetylation process affected their overall durability. We will use on-campus makerspaces in order to carry out these tests. The Brinell Hardness Test, the 3-Point Flexural Test, and the Anti-Swelling Efficiency Test will be used to grade the durability of the end product.

- In the future, this procedure will be repeated for each of the other four catalysts.

| Catalyst | Optimal Concentration | Standardized Concentration |

|---|---|---|

| Potassium Acetate | 9% | 3% |

| Zinc Chloride | 2% | 3% |

| N-Bromosuccinimide | 1% | 3% |

| Sodium Acetate | 0.1% | 3% |

| 4-Dimethylamino Pyridine | 5% | 3% |

Preliminary Results

| Group 1 (Control) | Group 2 (NBS) | Group 3 (DMAP) | Group 4 (Potassium Acetate) | Group 5 (Sodium Acetate) | Group 6 (Zinc Chloride) | |

|---|---|---|---|---|---|---|

| Before Drying | 9.2805 | 8.7411 | 9.1113 | 9.0964 | 9.2995 | 9.4256 |

| After Drying | 8.4724 | 7.9815 | 8.2974 | 8.2900 | 8.4719 | 8.524 |

| After Acetylation | N/A | 10.7748 | N/A | N/A | N/A | N/A |

We utilized cube groups 1 and 2 for our acetylation treatment with Group 1 as our control group and Group 2 as our treated group. Since Group 2 was the only group that underwent the acetylation process with NBS as its catalyst, only its weight was recorded after drying in the over for approximately 24 hours after its treatment. All groups experienced a significant weight loss after drying in the Quantitative Analysis Lab's oven because of a decrease in intrinsic moisture. This process was especially important for Group 2 to experience before its acetylation treatment as any moisture inside its cubes could have affected the reaction between the cubes, acetic anhydride, and the NBS catalyst.

Due to the MILL closing until January 2021, currently the only results we have to report are the change in mass after freshly cutting the blocks at the Aero Maker Space on campus, after undergoing the standard oven-dry procedure, and after the acetylation reaction, if applicable.

Durability Grading System

Wood samples will be subjected to a variety of tests in order to determine their overall durability. The three criteria chosen to examine are: hardness, flexibility, and dimensional stability, and weight percentage gain.

Brinell Hardness Test

For the test of hardness, the Brinell Hardness Test will be used. A 10 mm steel ball will be placed in the center of the wood samples and a predetermined force will be applied, using an ESM 303 machine. The diameter of the resulting circular indent will be measured and converted to Brinell Hardness Number (BHN) using the following formula:

Where P is the applied load, D is the diameter of the steel ball, and d is the resulting diameter of the indent. This BHN can be used to compare the wood samples to each other as well as to other types of wood with known BHN.

Three Point Flexural Strength Test

To test the flexibility of the samples, the Three Point Flexural Strength Test will be used. The test determines the amount of applied load required to break the treated sample. There will be two fixed ends and an increasing amount of force will be applied to the center of the sample and recorded when it breaks. The flexural strength can be calculated using the formula:

Where F is the maximum force applied, L is the length of the sample, w is the width of the sample and d is the depth of the sample.

Dimensional Stability

The dimensional stability of the samples will be calculated through calculating the Anti-Swelling Efficiency (ASE). Treated samples will undergo 10 cycles of repeated liquid water saturation and oven drying at 105°C. After each cycle the Anti-Swelling Efficiency will be calculated using the formulas:

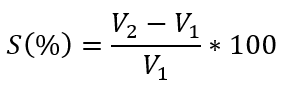

Where Sr is the volumetric swelling coefficient of the untreated samples, and St is the volumetric swelling coefficient of the treated samples. The volumetric swelling coefficients were calculated according to the formula:

Where V2 is the volume of wood after soaking and V1 is the volume of wood before soaking. After each cycle the samples will also be examined for signs of cracking and/or deformations which will be recorded.

Water Absorption

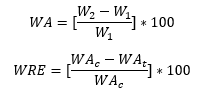

Oven-dried wood specimens will be placed into a 500 mL beaker filled with deionized water. Every 24 hours, for 14 days the specimens will be removed from the beaker and dried with a tissue. Their dimensions and weights will be recorded and then again placed in the beaker and the water replaced. Any visible changes to the wood's surface (color, indentations, etc.) will be recorded. Relative water uptake (WA) and water repellent efficiency (WRE) will be calculated daily using the following equations:

Where W2 is the wet weight of the wood specimens after wetting with water, W1 is the initial dry weight, WAc is the water absorption rates of untreated controls, and WAt is the water absorption rates of treated specimens.

Milestones

1/16/20: First team meeting

2/11/20: Team selection of experiment - wood acetylation with use of acetic anhydride during catalyst reaction

2/13/20: Five catalyst selections made official

2/25/20: Completion of final project proposal

3/08/20: Dr. Leavey informs team about opportunity to present to Georgia Forestry Professionals on 04/02

3/12/20: Team visits HIVE workspace to experiment with wood cutting and modifying and gain tips and advice from PI present

9/09/20: Team switches to loblolly pine instead of radiata pine because of differences in sustainability measurements between the two types of wood

9/22/20: Team visits Invention Studio Wood Workshop to experiment with Accoya wood samples and the makerspace's wood machinery

10/16/20: Team finished acquiring all loblolly cube samples needed for acetylation treatments at Aero Makerspace with the help of PIs present

10/28/20: Cubes are retrieved from Quantitative Analysis Lab in Boggs and placed into desiccators and are ready to be used for treatment

11/11/20: Team meets with Dr. Leavey, Dr. Evans, and Dr. Zhu over Bluejeans to discuss new apparatus requirements, lab scheduling, and sustainable and available methods for the acetylation process

11/17/20: Team transports apparatus materials (glassware, acetic anhydride, cubes inside of desiccators) with the assistance of Dr. Leavey, Dr. Evans, Dr. O'Mahoney, and Dr. Zhu

11/19/20: First acetylation treatment experiment with the use of N-bromosuccinimide as catalyst is completed! (6pm-9pm CULC 578)

Analogous Systems

Hitchcock Center for the Environment (Amherst, MA)

- Wood: eastern white cedar, oak

- Certified Living Building

- Responsible industry imperative: site-harvested or salvaged

- Embodied carbon footprint imperative: all-wood frame and shell system

- Red List: issues with lighting fixtures and a concrete artist who formerly used toxic pigments in his art

- Conservation & reuse: end-of-life recycling and compost

- Resources: [1]

Sustainable Buildings Research Centre (Wollongong, Australia)

- Wood: FSC timber products

- Certified Living Building

- Responsible industry imperative: FSC certified or obtained from salvaged sources

- Embodied carbon footprint imperative: dematerialization strategy whenever a single product could fulfill multiple roles

- Red List: soffit insulation; only product to meet all criteria was spray-applied paper pulp product; required exemptions of Red List included lead, PVC, and formaldehyde

- Conservation & reuse: use of The Material Conservation Management Plan (strategies used to eliminate production of waste during life cycle)

- Resources: [2][3]

Frick Environmental Center (Pittsburgh, PA)

- Wood: black locust wood

- Certified Living Building

- Responsible industry imperative: local artists, woodworkers, and landscape artists who created artwork for the center using recycled materials and sustainable practices

- Embodied carbon footprint imperative: all equipment used met EPA's Tier 4 Standards for engine emissions; modified work schedule (4 days, 10 hours) reduces carbon footprint

- Red List: materials that did not require treatment, stain, or sealant, such as concrete, steel, stone, aluminum, and black locust lumber were used in project

- Conservation & reuse: pre-sorted debris on site from previous building, green cleaning and purchasing guidelines to promote recycling, triple-receptacles to promote sorting materials for composting or recycling

- Resources: [4]

Old Oak Dojo (Boston, MA)

- Wood: locally-available oak, locally and responsibly sourced structural plywood

- Certified Living Building

- Responsible industry imperative: using donations of salvaged wood or completing deconstruction projects; paying higher prices on Reuse Center (a non-profit) items to help organizations continue sustainable business practices

- Embodied carbon footprint imperative: using reclaimed surplus material and a heavy reliance on sourcing locally salvaged materials to reduce carbon impact

- Red List: challenges were mostly in electrical components and some products that used "cured resin solids" with <0.1% formaldehyde for surface coatings; a foam control insulation board contained <1% of HFR. To combat this, the team analyzed each non-complying product and researched the healthiest product available, even having products custom manufactured for the building.

- Conservation & reuse: use of truss joints, crushed stone, marble tiles, structural brick piers, and usable dimensional lumber found onsite or from deconstructed buildings. Unusable products were recycled.

- Resources: [5]

Macquarie University Innovation Hub (Australia)

- Wood: Accoya

- Description: Wood was chosen as the major material so that it could be disassembled and relocated for reuse. Accoya wood was selected for its Class 1 durability, stability, and sustainable credentials. Other wood products used were Victorian iron ash, double-glazed timber, birch ply, Binderholz 3-ply panels, and spruce glulam.

- Resources: [1][2]

Tashjian Bee Pollination Center @ University of Minnesota (Minneapolis, MN)

- Wood: Accoya

- Description: In the construction of the Bee Pollination Center, the university was interested in taking a modern, sustainable alternative to wood. Materials were assessed based on local availability, durability, and whether it met the standards of sourcing and sustainability. Accoya wood was used in the external cladding of the building and was used in both a stained and charred form for aesthetics.

- Resources: [3][4]

Copenhagen University - "The Wild Campus" (Denmark)

- Wood: Accoya

- Description: The wood would be used to create outdoor furniture. Accoya wood was selected because of its sustainable origins, durability, and resilience to the environment. The furniture would remain outdoors year-round, so it was important to select a wood that could resist pest infestation and swelling and rot from water damage.

- Resources: [5]

Annotated Bibliography

Bang, S. S., & Johnston, D. (1998). "Environmental effects of sodium acetate/formate deicer, Ice Shear™." Archives of environmental contamination and toxicology, 35(4), 580-587.

Bang and Johnston discuss the environmental impacts of sodium acetate using biochemical oxygen demand (BOD) tests, chemical oxygen demand (COD) tests, acute rainbow trout bioassays, and phytotoxicity tests. BOD and COD tests concluded that runoff of sodium acetate may cause oxygen depletion for a short period of time. However it is relatively harmless to rainbow trout and vegetation, and may act as a fertilizer for some plants.

Giang, L., Cuong, C., Hoa, T., and Loc, T. (2015). "Acetylation of Microfibrillated Cellulose by Reaction with Acetic Anhydride Catalyzed by N-Bromosuccinimide." Tạp chí Khoa học và Công nghệ, 53(3), 333-339. Retrieved February 13, 2020, from http://vjs.ac.vn/index.php/jst/article/view/5769/5704.

In this paper, Giang, Cuong, Hoa, and Loc investigate chemical surface modification of microfibrillated cellulose with different chemicals, such as acetic anhydride, which is used in wood acetylation. N-Bromosuccinimide was used as a catalyst, and dimethyl sulfoxide was used as a solvent. There is no recorded procedure in this paper, but there is a lot of analysis using IR spectroscopy. H-NMR, powder X-ray diffraction, and thermal stability tests also were used to analyze results of the experiment.

Hill, C. A. S. (n.d.). "Potential Catalysts for the Acetylation of Wood." Holzforschung, 54, 269–272. Retrieved from https://www.degruyter.com/downloadpdf/j/hfsg.2000.54.issue-3/hf.2000.045/hf.2000.045.pdf

This paper dicusses about the use of different types of tertiary amines as catalysts in wood acetylation. The general process involves submerging the wood in an acetic anhydride/catalyst blend (either 1%, 5%, or 10% of catalyst). DMAP is shown to exhibit the fastest rate of reaction. NMP showed lower rate of reaction initially, but after 5000s, the reaction speed exceeded that of DMAP. NMPO didn't have an effect on the acetylation process. The optimal functioning concentration for DMAP is also determined.

Li, J. Z., Furuno, T., & Katoh, S. (2007). "Wood propionylation in the presence of catalysts." Wood and fiber science, 33(2), 255-263.

The paper discusses the process and results of using a variety of different catalysts to acetylate Sapwood specimens of hinoki and yellow-poplar with a size of 30(R) × 30(T) × 5(L) mm. The catalysts used in the experiment were: Potassium acetate, Sodium acetate, Sodium propionate, Sodium thiosulfate, Potassium sulfate and sodium sulfate, Sodium tetraborate decahydrate. In order to acetylate the wood, samples were submerged in solutions containing catalysts, and then immersed in propionic anhydride or acetic anhydride, with oven drying and reduced pressure between each step. The results were discussed, using dimensional stability and color changes as the criteria for evaluation.

Li, J. Z., Furuno, T., Zhou, W. R., Ren, Q., Han, X. Z., & Zhao, J. P. (2009). "Properties of acetylated wood prepared at low temperature in the presence of catalysts." Journal of wood chemistry and technology, 29(3), 241-250.

The acetylation of sapwood and its performance is tested using sodium acetate, zinc chloride, magnesium perchlorate, and magnesium chloride hexahydrate as catalysts. Acetylation was performed with catalysts dissolved in acetic anhydride solution. Evaluation of acetylated wood was determined using dimensional stability, modulus of dynamic elasticity, static modulus of elasticity, bending strength tests, and color change using the l*a*b system.

Nagarajappa, G., Pandey, K., Shinde, A., and Vagdevi, H. (2015). "N-Bromosuccinimide (NBS) - An Efficient Catalyst for Acetylation of Wood." Holzforschung, 70(5), 421-427. Retrieved February 13, 2020, from https://www.academia.edu/19903304/N-Bromosuccinimide_NBS_an_efficient_catalyst_for_acetylation_of_wood.

In this study, Nagarajappa, Pandey, Shinde, and Vagdevi investigate the effects of N-Bromosuccinimide as a catalyst for the acetylation of wood. The wood samples were reacted at temperatures of 105*C and 120*C, at five different time intervals. The results of the experiment were observed and quantified using spectrometry and moisture absorption (equilibrium moisture content), relative to different humidity conditions. Some of the findings were that the degree of acetylation significantly increased with concentration of the catalyst, reaction time, and temperature. This paper serves as a general guideline for working concentrations of NBS.

Sun, R. C. (2004). "Effect of tertiary amine catalysts on the acetylation of wheat straw for the production of oil sorption-active materials." Comptes Rendus Chimie, 7(2), 125–134. doi: https://doi.org/10.1016/j.crci.2003.10.010

This article specifies procedures and results of tertiary amine-incorporated acetylation process for wheat straws." Something worth mentioning is that the research on wheat straws is valuable due to its structural and biological similarity to that of pine wood. By looking at how wheat straws reacted to wood acetylation in which tertiary amines serve as catalysts, researchers expect to see similar results in wood. It is mentioned that the resulting wheat straw was more thermal stable and exhibits increased hydrophobic abilities, although a sustainability delimma exists where effective penetration of reagents cannot be ensured. DMAP is found to be the most effective catalyst, which is in agreement with similar researches.

Team Members

| Name | Major | Years Active |

|---|---|---|

| Silas Ever | Biology & Computer Science | 2019 - Present |

| Lily Luong | Environmental Engineering | 2020 - Present |

| Sarah Rohlfsen | Environmental Engineering | 2019 - 2020 |

| Manlin Xu | Earth and Atmospheric Sciences | 2019 - 2020 |